Innovative gas purification using ionic liquids

In TP 107 technology development for biogas cleaning with ionic liquids (IL) was carried out. Using IL, CO2 can be separated via quasi-isothermal chemical gas scrubbing.

In a first step, suitable IL had to be identified. In analogy to conventional amine based scrubbing media, IL based on primary, secondary and tertiary amine constituents were examined. The IL were characterized experimentally in terms of absorption capacity, absorption enthalpy and absorption rate for CO2. As an outcome of the experiments, the ionic liquid [BDiMIM][Pro] was identified as suitable for the process. To reduce the viscosity of the scrubbing liquid [BDiMIM][Pro] was used in mixtures with [BDiMIM][BTA.

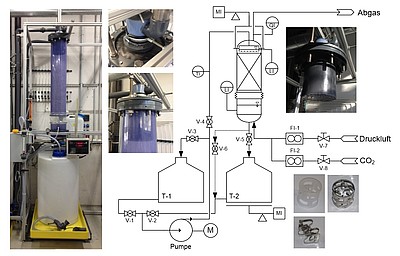

Experimental investigations on hydrodynamics and mass transfer of CO2 in viscous and well-wetting liquids were conducted. Mass transfer kinetics are needed for the design of packed column reactors. Since in most cases common design equations are valid only for aqueous media, they cannot be used without further validation for ionic liquids. Therefore, an experimental apparatus for the determination of the dynamic liquid hold-up hL,dyn and the droplet fraction FD in the packing as well as for the liquid-side volumetric mass transfer coefficient βLae was established within the project. The modeling of the mass transfer processes in the packing is based on the experimental results obtained. The model is based on an existing literature approach which was modified for ionic liquids. The experimental results were used to validate the derived model, which is able to give adequate predictions for IL based scrubbing media.

In addition, the general feasibility of the IL-based process was tested in mini plant experiments where continuously operated separation of CO2 / CH4 mixtures was carried out. On the basis of the experimental results it was possible to prove that the process concept is suitable to produce a ready to feed-in biogas quality (yCO2 < 5 % by volume). Furthermore, the investigated process concept features an energy saving potential of approximately 50 % compared to state of the art biogas upgrading technologies.

| Project title | Power-to Gas concepts using biological methanation: Development of an innovative gas purification process on the application of ionic liquids |

| Institution | Karlsruhe Institute of Technology (KIT), Engler-Bunte-Institute, Fuel Technology Division |

| Research group | Prof. Dr.-Ing. Thomas Kolb, Felix Ortloff |

| Project status | completed |